Please note that the photographs are added for interest but do not necessarily relate to the adjacent paragraph.

History

When Rick bought his Mercedes 'A' Class in February 2005 he was well impressed and being a 2001 A170CDI he knew that he was not only benefit from the economy of the diesel but also the torque. He had bought the car from a Subaru Garage, Lucas of Mansfield and as well as having been told it had been subject to a 121 point inspection and safety check also made sure that the car would be covered by a warrantee period, which was

three months even though the car had only covered 38000 miles. One could ask at this point, with belt and braces how could he go wrong?

Rick drove his prize possession home, and like many of us did his own inspection producing a list of defects as long as your arm, which included steering column, front brake discs, blown bulbs and even white indicator bulbs in white reflector housings. The garage supplying the vehicle took all this onboard and the work was carried out at a Mercedes Garage.

Rick drove his prize possession home, and like many of us did his own inspection producing a list of defects as long as your arm, which included steering column, front brake discs, blown bulbs and even white indicator bulbs in white reflector housings. The garage supplying the vehicle took all this onboard and the work was carried out at a Mercedes Garage.

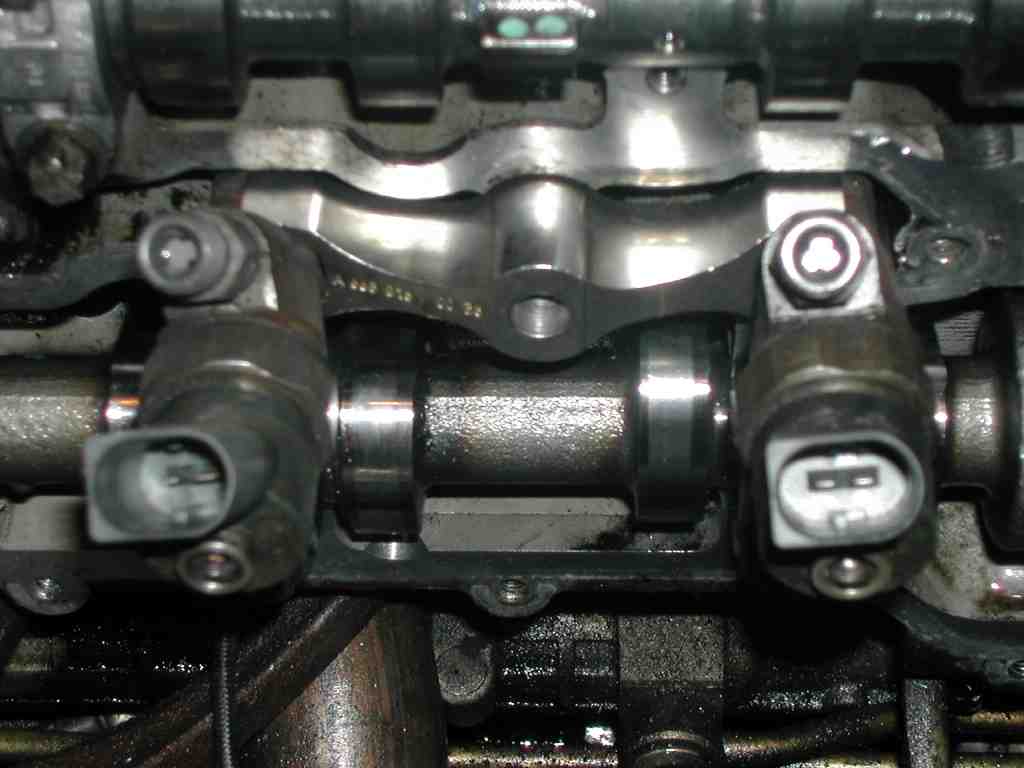

Some six weeks later after having done several long runs Rick became aware of a problem due to what appeared initially to be an oil leak on his driveway inspection revealed that the under-body panel was also covered in an oily residue, as a result it went back to the retailer again. This problem led to the car going back a total of seven times before the fault was a leaking injector was located and the cause of the problem.

After the final visit and some 5 months later the problem appeared to have been corrected and Rick got on with life and the pleasures of driving a Mercedes, by this time the car had covered 45000 miles.

However this was relatively short lived when after covering only another 6000 miles during which time the car had run well, Rick suffered the experience of having an injector blow on his engine, an experience he would not want repeated the engine sounded and ran like a tractor rather than a Mercedes-Benz and the incident could well have caused a serious accident.

It now appears that the garage where it took 5 months, and 7 visits to locate a leak on an injector, instead of doing a professional job had merely applied more pressure to the injector retaining bolts (torque bolt and claw) and in doing so had stripped or severally weakened the threads by over tightening.

(Another good reason for always using a torque wrench,

not just to ensure that bolts are tightened but also not over-tightened.)

On close inspection it was obvious that it was this that had led to the injector being blown from its seating.

By this time the car was out of the retailer's warrantee period for the work that had been carried out and of course the garage would not admit to having bodged the job anyway he also realised now that it was a total waste of time taking it to this particular garage, if they had bodged the job once then there was every chance they would do it again. And as Rick himself says "he would rather let a Typhoo Tea chimp work on it than take it back to that garage" A little unfair to chimp's but I can appreciate his sentiment.

Rick was awqare that if Mercedes were involved he would be confronted by a very large bill. for not just the engine problem but also rear springs which also needed replacing,

However he now had to make a decision because the car wa now a none runner.

However he now had to make a decision because the car wa now a none runner. After some thought he decided to investigate the possibilities of doing the job's himself.

Like the rest of us he found that his problem was exacerbated by the fact that there is very little information available on the car and that no Haynes manual exists, however e-mails that run into double figures to and from lofty resulted in him having sufficient information to assess the situation, and as a result he started the job.

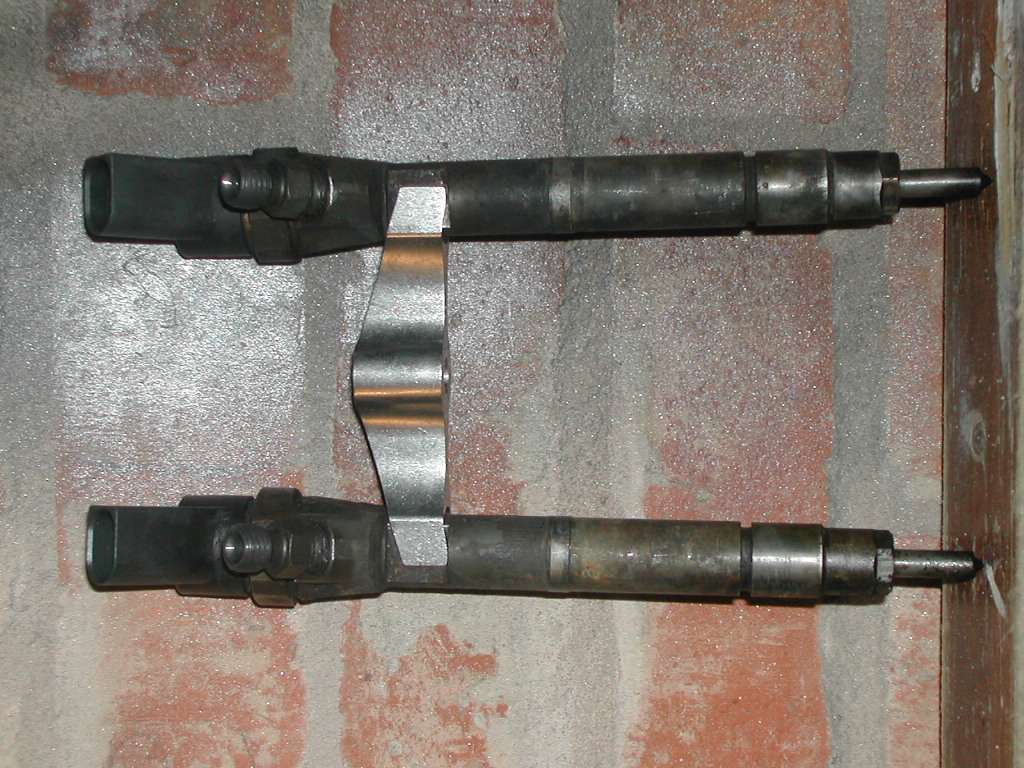

His first major problem was getting the stripped thread replaced and a new bolt of the length and thread provided, this could not be a standard Mercedes replacement bolt as the head of the engine had to be re-tapped (drilled and re-threaded) to replace the damaged thread, this resulted in using an 8mm diameter bolt, but the mechanic contracted to undertake this work cut a number 1 pitch thread (fine thread) so as to afford more torque, as is the case with the Mercedes thread, although this was a sound idea in theory it proved the cause of yet more problems as that thread value was not available, off the shelf on an 8mm bolt, which is normally 1.25 pitch, so Rick had to get the bolt made. Never the less undaunted he managed to find a company that was able to supply the bolt, in fact he ordered two. The injector that had been released/blown from its housed position due to the defective bolt was

re-usable but Rick had cut the retaining claw away to enable him to remove it, one more component that would have to be replaced, however the blown injector was salvaged.

Next problem, close inspection revealed the neighbouring injector held by the same claw and bolt had either leaked or was subject to heavy carbon deposits from the original or recent this needed to be checked out, Rick knew he was wasting his time if he just ignored it and so he decided to remove this second injector.

This however was easier said than done as it turned out the second injector was well and truly stuck in the engine and it appeared nothing was going to move it.

Rick spent a great deal of time struggling to remove this injector and tried all manner of things including soaking the area with solvents to try and break the seal of the baked carbon deposits, he did manage after a considerable period of time to move it slightly but that was it.

Rick was in a catch 22 situation he really needed to remove the camshaft cover to be able to get at the injector but the injector had to be removed before the cover could be removed.

Rick was aware that in the process of working on this difficult injector he would cause some minor damage to the cover and so had decided to replace it anyway, he therefore broke the cover away to provide him with the space he needed.

Further attempts at its removal still failed and so Rick decided to confront the situation head on, a drastic situation calls for drastic measures, he decided to weld, yes weld a socket to the head of the injector; this would

Further attempts at its removal still failed and so Rick decided to confront the situation head on, a drastic situation calls for drastic measures, he decided to weld, yes weld a socket to the head of the injector; this wouldenable him to attach a ¾ drive bar to the

injector, that along with an extension bar did the job and the injector much to Rick's relief was out.

This injector along with the camshaft cover, & claw would need to be replaced and so he ordered the these items from Mercedes, the injector was ordered from United Diesel www.uniteddiesel.co.uk at a cost of £150.00 who offered a refund on undamaged injectors, next day delivery, albeit the refund aspect wasn't going to be applicable in Rick's case, as his stuck injector still had his socket welded to the top of it.

However the price was only half of the Mercedes parts price, even without the refund and although the one purchased was reconditioned it had got a brand new Mercedes head on it.

Rick removed the two remaining injectors without incident, and these cleaned and coated with copper slip grease (MB Special grease) before being replaced and tightened down with the claw and torque bolt.

This is apparently a common problem on Mercedes-Benz diesel engines and can result in extreme cases of a replacement engine having to be fitted, the labour charge of trying to remove these stuck injectors being the prohibiting factor.

This is apparently a common problem on Mercedes-Benz diesel engines and can result in extreme cases of a replacement engine having to be fitted, the labour charge of trying to remove these stuck injectors being the prohibiting factor. If there is anything that Mercedes-Benz diesel owners can learn from this experience its that if you see even a suggestion of a leak on an injector or under the car, not to confused with water dripping of the air conditioning pipe-work, then get it sorted and soon. If you have unexplained oil deposits on the your drive or garage floor check it out, it could well be a diesel leak that has so far gone undetected. That way you will possibly avoid the experience that Rick encountered.

If there is anything that Mercedes-Benz diesel owners can learn from this experience its that if you see even a suggestion of a leak on an injector or under the car, not to confused with water dripping of the air conditioning pipe-work, then get it sorted and soon. If you have unexplained oil deposits on the your drive or garage floor check it out, it could well be a diesel leak that has so far gone undetected. That way you will possibly avoid the experience that Rick encountered. The other lesson than can be learned from Rick's experience is, if you have a leak on an injector do NOT just tighten the torque bolts and claw , you could well finish up with the same problem as Rick. Remember there is no substitute for a replacement seal on the injector, which would not be a difficult job to replace on its own. Only when the leak is ignored for a period of time or the wrong action taken to correct it will problems of the type experienced by Rick be experienced.

The over tightening of clamps and other fittings can be avoided by the use of a correctly set torque wrench.

No doubt some of you are wondering what happened about the rear Springs on Rick's car, well he fitted them without problem while waiting for the spares from Mercedes-parts and United Diesel www.uniteddiesel.co.uk

Such was the complexity of the injector job that Rick's rear springs replacement paled into insignificance.

I would love to tell 'A' Class diesel owners that the above incident was a one off, sadly that is not the case and many owners have suffered this problem with varying degrees of difficultly and cost, we have had owners sell cars, trading them in to get the best price for what is a problem engine, no doubt for the car only to finish up at the nearest car sale rooms, replace their engine, and in some cases undertake the repairs themselves some with great difficulty but with the now satisfaction of knowing their engine is know mechanically sound. But cases without problems when trying to remove the injectors to my knowledge are rare, as the leaking diesel carbons up the bore into which the injector is housed and it appears nothing will then move them.

This is just one more mail I have received on the subject.

No doubt Mercedes would deny there is a problem, as they do to most problems are highlighted to them, such as the loom abrasion issue I raised with them recently, but we as owners know different, even their technicians with all their sophisticated knowledge, protective gloves & equipment are fitting replacement engines at great cost to the owners because of the stuck injector problem is taking so long and are so difficult to remove, if ever that's it's cheaper and quicker to fit a replacement engine. Come on lofty, I hear you say, that can't be the case surely MB are aware of how to get these out after all they have hydraulic tools that can remove them! Well read on :- Quote.

Dear lofty

I have been consulting your website on the A class since my Diesel A170, auto clutch, Year 2000 suffered a leaking injector!

I have just read your page 65 in which you refer to knowing of 1 person who had to spend thousands on a new engine.

You can now add another! In short I left the car with 78000 miles on it in with my usual garage (not Mercedes specialist) last year.

At the time I asked him to check the other 3 injectors as it was explained to me that the seal consisted of a simple copper ring.

It seemed sensible to replace all seals as once the injectors were exposed. BIG MISTAKE! The leaking injector popped out once the finger clamp was released and the engine turned over. On trying to release the other 3 the mechanic managed to loosen them but they wouldn't budge. Thankfully I was due to go on holiday and the garage was also able to lend me a car during the period that the car was off the road? To cut a long story short, determined, he tried everything, acid based release agents soaking for days at a time, injector extractors including a couple of custom made devices. He sought advice from a specialist mechanic friend at the local Mercedes dealer. etc etc.

I in the meantime started trawling the web (discovered this site) and began to realise the frightening reality. Even if removing the injectors with a welded on bar worked, the fact that this is such a common problem means that reconditioned injectors are not easily come by.

The price of new injectors some where around , £250.00 each (can't remember if that is vat inclusive or not - probably not). The decision had to be made. Although the car was just a few months off being 8 years old , it was in excellent condition - forgetting the engine of course. To just walk away or fit a new engine. In the end I decided on a new engine. Mercedes sell these for under £1500 inc vat. This seemed to be the obvious decision when comparing the cost of new injectors and to walk away didn't seem acceptable. ( I tend to hang on to cars until the death) Of course once this decision was made the extra costs began to mount. As the starter motor is so inaccessible as explained in your pages I asked the garage to have it checked, and it was duly serviced. New hoses etc etc resulted in a final cost of £3000!!!!!! and this following an off the road period of 3 months!!!!, never mind the lost road tax!!!!!!

Got back on the road in September last year. The new engine goes great but for how long? It comes with a 12 month Mercedes warranty which, I do not expect to make a claim against.

I am now in the unfortunate position of having a car which owes me a few years of trouble free motoring otherwise I will have simply thrown 3 grand down the drain! If I sell, I can not expect to recover anything like the cost of the new engine. Apart from the well known fact that the A class is a bag of rattles, I really like the car and utilise its practical set up frequently - seats out etc. Immaculate condition at 3 1/2 years old, the fact that it had a Mercedes diesel engine seemed like a big bonus?

It seems to me that to be able to buy a new engine so cheaply says a lot - they must go through a lot of these things, can't remember seeing a made in China sticker but then I didn't look that closely! Anyway that's probably unfair to the Chinese!

I'll stop there as I can feel some serious? cynicism? welling up inside me (I may have cried at the time?)

Attached to the engine is original gearbox. Keep up the good work Regards William. Unquote

And an another mail which may help solve a number of 'A' Class diesel owners problems,

Quote

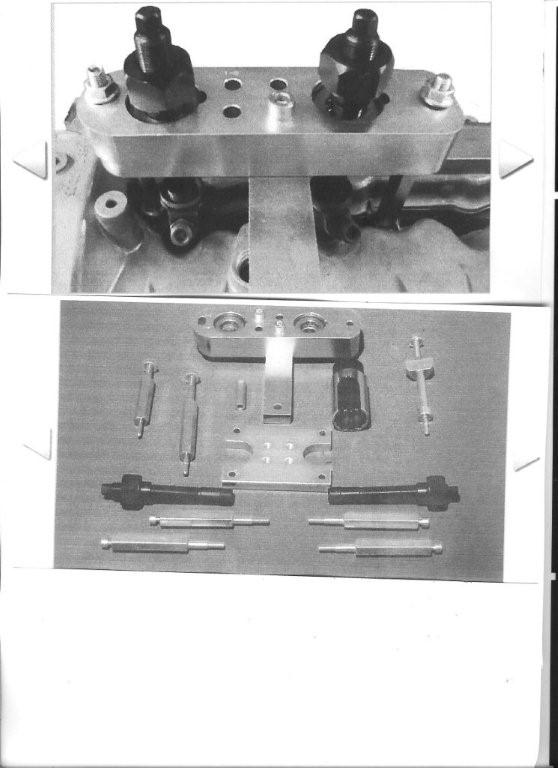

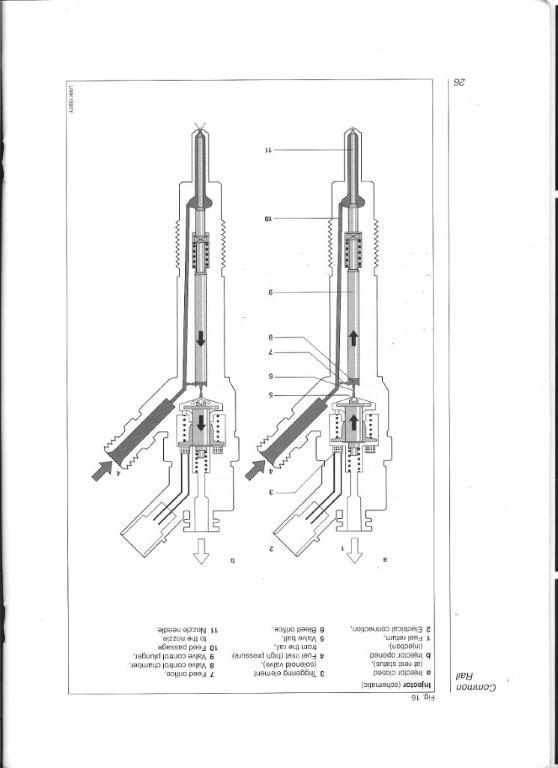

Hi Albert, I have a 1999 diesel A-Class and since I am a retired electronics engineer I cannot afford the main agents so I bought your excellent CD which I must say is magnificent, keep up the good work. On the subject of stuck injectors, the car stopped at traffic lights a few weeks ago with a puff of white smoke from the bonnet, continued to run on three cylinders for about a mile and stalled when trying to turn right, I suspect the power steering loaded the motor beyond endurance. Suspecting a blown head gasket I bought a set of head bolts, gasket and top set, which I still have, maybe I should keep them handy on the principle that carrying a raincoat stops it raining. Not wishing to dismantle the engine on my drive, I asked my MOT garage what they thought. On inspection the van trained mechanic, one Dale Pilling of Blackpool Service Centre diagnosed a blown injector on No. 1 cylinder. When it was accessed he found the cast steel bridge that secured both 1 &2 injectors had failed and we thought that it had been cracked when being torqued down at the factory! A new bridge/clamp and 6mm bolt + a second fixing bolt for 3&4 injectors cured the engine perfectly. The main problem was the removal of the no2 injector which had to be inserted alongside already loose no1 with the new bridge fitted between them. Snap-On supply a kit with a bridge on pedestals with ball races to ease the load on two mandrels which screw into the top of each injector after the removal of the electromagnetic ball valve for which a modified tubular socket is also supplied. The use of this or similar devices removes the stuck injector gently ( no slide hammer) without the need to damage the valve cover. If you need, I can supply images of these and a Bosch injector internals diagram from their excellent manual 'Diesel accumulator fuel injection system Common Rail 1 997 722 175 'which I highly recommend. The total cost of the repair was trifling by a young man with experience gained on the repair of Vaneo engines in MB commercial vehicles who actually used a single tubular spacer and mandrel with ground down tubular sockets to stand off the spacer from the cover. Total parts required 2x 6mm bolts 1x cast steel injector retainer clamp. After reading all about the disasters within your website/CD I was extremely impressed by the performance of Dale Pilling of Blackpool Service Centre 01252 885316 Many thanks for the helpful advice on a difficult mechanism. Jim Kirkman Unquote

Jim has also sent the attachments.

And thank you Jim for the information and attachments, when your in a tight spot all information helps.

Hi Lofty,

Great website and incredibly useful information. I would just like to add my thoughts on the problem with the A170 sticking / blowing injector issue.

For a few months I had been experiencing a fume's type smell in the cabin (think exhaust). On inspection of the no. 1 injector, sure enough this had been blowing and as a result had pretty much encased no. 1, much of no. 2 injector and almost all of the claw and bolt holding the injectors in place with a carbon residue that was incredibly hard and brittle and very difficult to remove. As identified by the information on your website, I was now faced with a problem of successfully being able to remove the injector in order to be able to reseat with a new copper seal.

I described the problem to a diesel engine technician friend who has worked on pretty much every diesel engine this side of 1980. His solution to remove the carbon build up? A liberal coating of Nitromors paint stripper on the carbon to be left overnight!

Being somewhat sceptical, I carried out his advice and liberally applied a couple of coats of Nitromors, being careful not to get any on the surrounding plastic surfaces (in particular the plastic shrouding on top of the injectors) and left this overnight. Sure enough, the following day, the Nitromors had done its job and greatly softened the carbon to an extent it could be dug out with a screwdriver, exposing the clamp, bolt head and pretty much all of the no.1 and no. 2 injector. And I am pleased to say that upon removal of the bolt and clamp, both injectors could be removed with a little carefully applied force.

Once removed from the engine, I cleaned the remaining carbon deposits with a wire brush, installed new copper washers and using a new bolt, re-seated the injectors, clamp and re-torqued. And I am pleased to report that this has cured the blowing injector / fumes entering the cabin. I would only add that whilst doing this job, I was careful to make sure that as little Nitromors / carbon muck fell down the injector bores when the injectors were removed. As a precaution, I also put a thin piece of hose down injector bores and applied a vacuum to suck out any remaining muck that may have fallen down.

I am hoping that by sharing my experiences, this information can be used by other A Class owners to avoid costly repair bills on what appears to be an all too common problem on the diesel engines. As such, please feel free to use whatever information I have provided as you see fit on your website and CD. All the best

Howard Stimpson

Thank you Howard for your contribution, it looks as though if used with extreme care 'Nitromors' is the answer But I cannot over emphasise the with care bit enough.

WARNING NITROMORS It is strongly recommended you wear eye protection and protective gloves. Any contact with the skin should be washed off immediatly with copious supplies of cold clean water. 'Nitromors' will cause chemical burns if it comes into contact with the skin. Read the instructions fully before use.

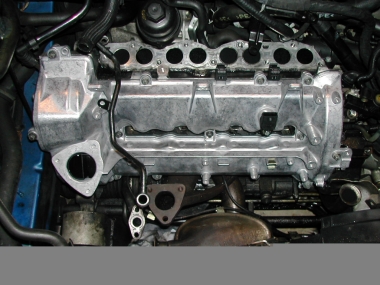

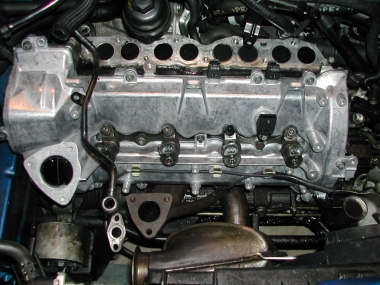

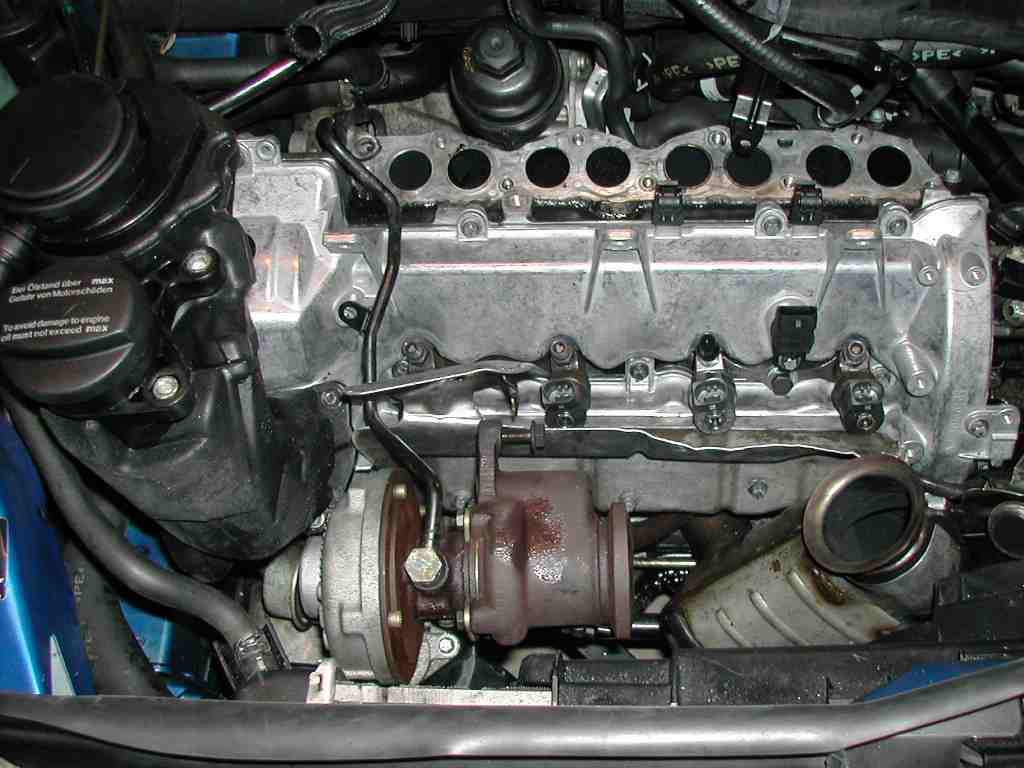

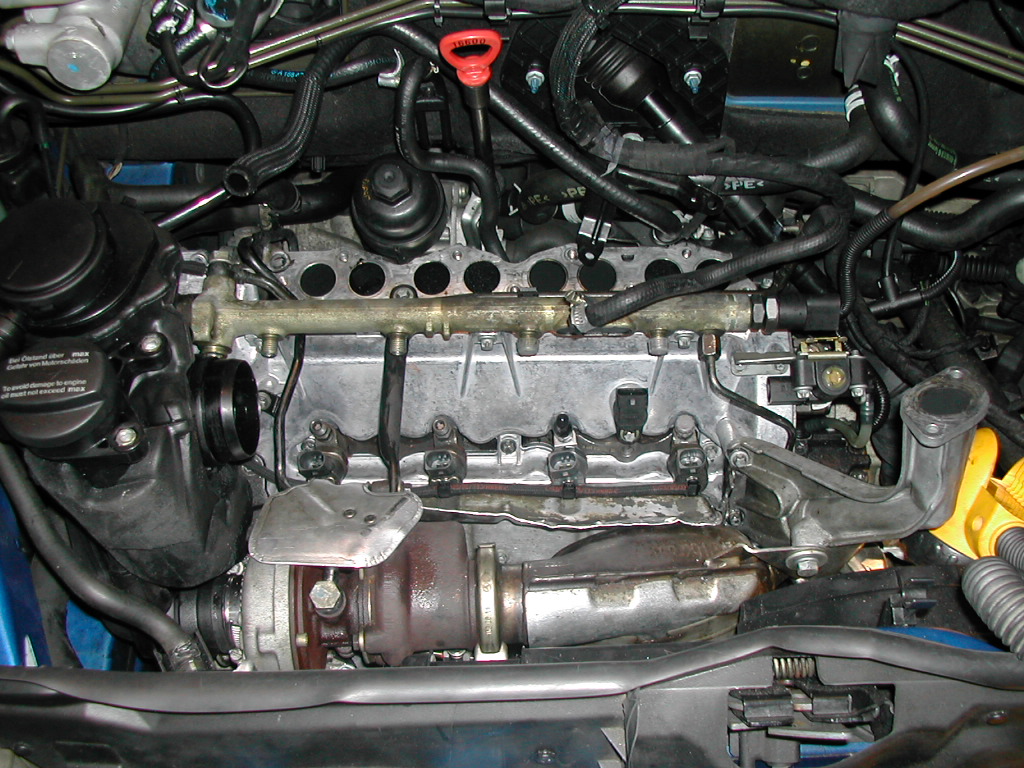

John's Photographs France.

John in France who removed the engine from a recently purchased A class A170CDI because of a noisy gearbox also made this discovery, no doubt some of the engine transmission noise has been caused by the leaking injectors. Good luck John

A170CD1 refused above 30-40MPH

For those of you with diesel A class being it W168 or W169 be aware of this problem and keep an eye out for leaking injectors, Full service history or not.

This information has been doanated by Mike, the second owner in a Month to suffer this problem.

Johns Injector seating tool.

.jpg)

Dear Lofty,

Firstly, thanks for putting together such a great website with so much information.

Secondly, although I couldn't find the answer to my problem on your website, I thought i'd let you know the problem and the 'fix' - it's something a proper DIYer would probably have spotted straight away, but I'm a total newbie and so felt quite pleased with myself! Still, maybe it'll help someone else.

Car 2002 A170 (W168) CDi

Problem Generally a bit flat above 3000rpm, without much grunt. Also, when trying to overtake going uphill, the engine could suddenly lose power - no warning lights, no misfiring; just not much power and then the car going into 'limp home' mode. After switching the engine off and giving it a rest for a few minutes everything was fine.

Fix

I'd read about dodgy fuel filters, but knew that wasn't the problem; I then read your website about MAF problems and was considering trying to find, remove and clean the sensor.

Then i noticed the little black hose running from the offside end of the engine cover to a sensor on the bulkhead - it was worn and perished and only just hanging on to the spigot...

Apparently (as I'm sure you already know) this tube connects the engine to the manifold air pressure sensor, which obviously feeds in to the same ECU as the MAF sensor. Presumably with the engine under load, and with this tube leaking, the ECU got totally confused when comparing the manifold vacuum with the mass air flow data, and was just going to limp home for safety's sake.

So, I spent £1.99 for a bit of silicone tube from eBay (8mm external diameter, 4mm internal) and replaced the old tube (with plenty of slack to allow for the engine's movement), and the car now pulls smoothly up to 4500 rpm on any incline, and no more limp-home episodes!

I'm a bit surprised that MB would allow the entire engine management system to depend on one manky bit of rubber tube, but at least it was a cheap fix.

All the best, and keep up the good work with your website.

Mike

See also question 184 & 187 on page 3

This information has been provided by Martin who also had leaking injectors, he did the job himself with great success.

Well…. What can I say. Your library of information, illustrations, hints and tips is invaluable.

I removed the leaking injector and true to form it was number 1 near the turbo end. While I was there I also removed the other three and renewed the copper seals on each. This is not the first time I’ve replaced diesel injectors but it was by far the most complicated job because of the configuration of the engine layout.

I’ve replaced injectors and repaired leaking seals on several Fords, two Mercedes 220, and Peugeot 205, 206 and 207 and a Shogun over the last ten years and this little A170 was by far the hardest.

Let me pass on a small hint as to making the seal replacement a 100% success. After cleaning the injector housing seats and injector ends take a small amount of “Gun Gum” (exhaust sealing compound from a tube – it is smoother and flows better than the thick tin paste) and I mean a really small quantity and wipe it onto the surface of the copper sealing washer. It really only needs to be the merest smear because you don’t want it squeezing all out and around the injector nozzle. It wants to be just enough so that as the copper seal is compressed then the “Gun Gum” is squeezed out the diameter of the seal and no further.

This may sound like a real botch of a job but for those of us who are resealing injectors after 60 -70K miles and expect another 70k miles of uninterrupted service after all the hard work of replacing the seals then this is a pretty sure-fire means of ensuring that the seal remains bulletproof. From all of my previous seal repair / replacement work, I have never had a returning problem of a leaking copper seal.

The copper seals do not get immovably welded into position because the “Gun Gum” sets quite brittle and so when it is necessary to remove the seal again because an injector has failed then just a simple tap with a piece of plastic or aluminium rod is enough to upset the set “Gun Gum” and the copper seal can be picked out. Of course the bore and sealing surfaces needs cleaning and reseating but you would do that anyway after experiencing a leaking seal.

As for picking out the seals… if these are stuck in the injector bore and do not come away with the injector. Then get a 5mm piece of steel rod, hold the end against a grinder for a few seconds so that it forms a sharp burr over one side by about 1mm and then this can be used to pick the copper seal out from the injector bore because the sharp edge is able to pick its way between the copper sealing ring and the cylinder head injector seat.

By the way…

It is worth mentioning that it is not absolutely necessary to buy a fancy twin injector extractor. Once one injector has been removed by about ½ an inch the other will slide out quite easily with the injector clamp.

An Interesting problem…

If you find that after completing the job that you have no EGR vacuum then it is worth checking that all the hoses have been replaced correctly. The EGR valve is fed from the same vacuum circuit as the headlight level system. So if there is no EGR vacuum them you will find that your headlight levelling switch no longer works. The most likely cause is that you have probably not connected the vacuum hose back Number 11 in the diagram below (note 29 is the connection to the EGR valve):

Thank you Martin for your words of wisdom, good luck with your recent purchase.

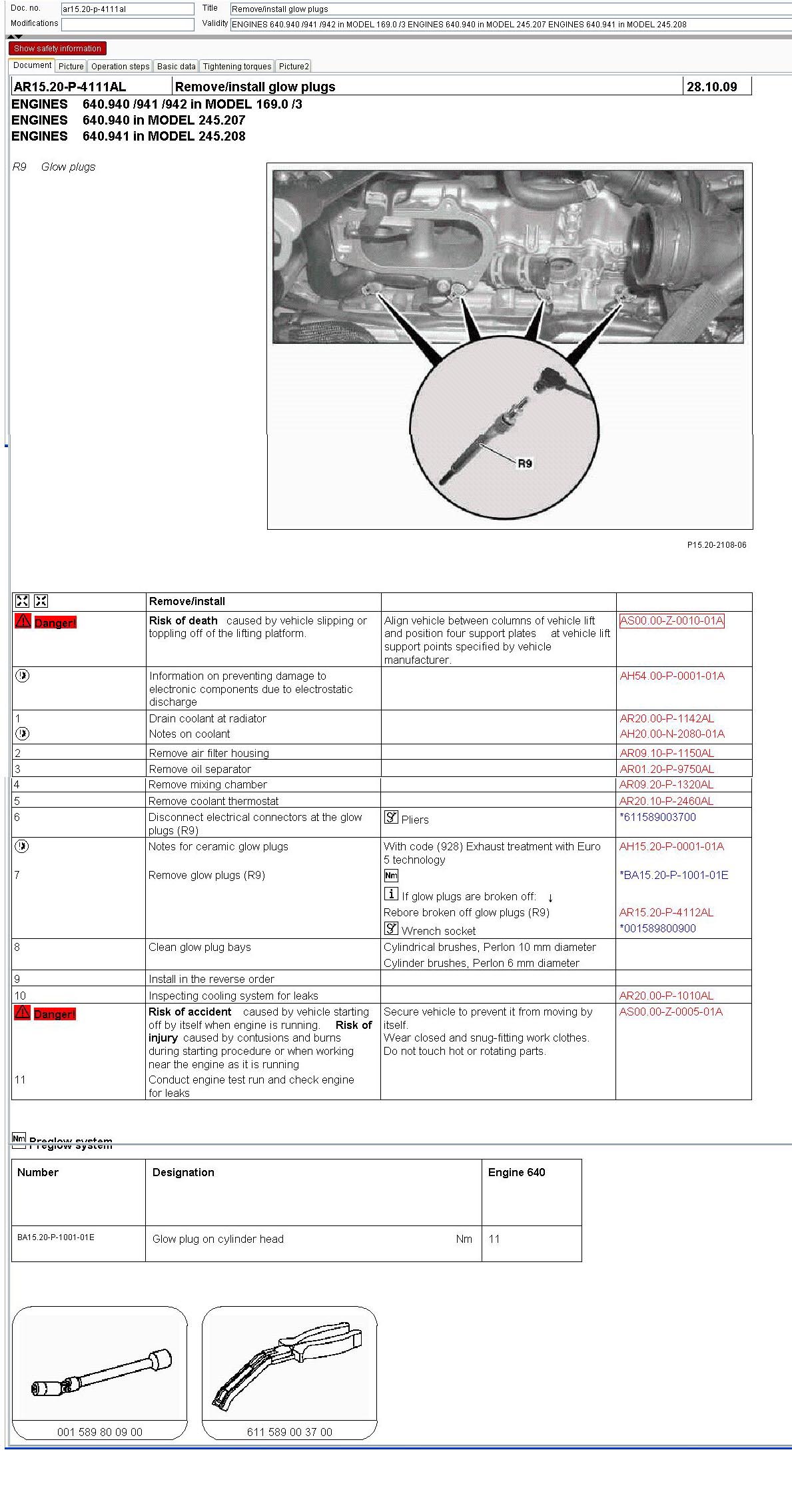

Location of Glow plugs on diesel models

Next.

Next.Back to Index,

Purchase DVD.

Please Make a Donation.